CURTI Costruzioni Meccaniche S.p.A.

Contacts

Description

CURTI was born in Imola in 1955, a manufacturer of spare parts for textile and agricultural machinery with about ten employees.

Today is based in Castel Bolognese (RA) and made up of 5 business units with over 600 employees in a group, divided into ten companies in Italy and around the world.

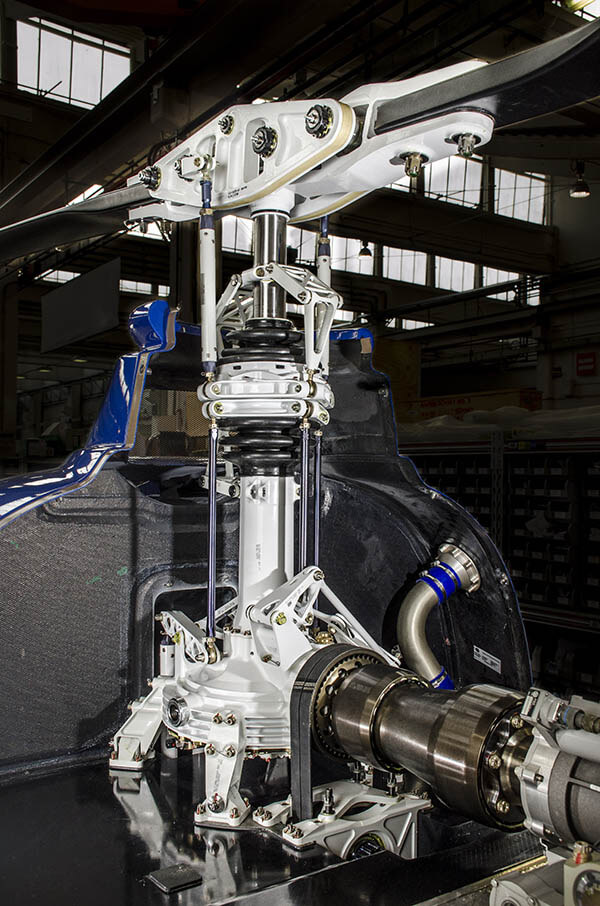

CURTI is a leader in the supply of aeronautical systems and services, thanks to recognized reliability and high-quality levels.

The notable collaborations with companies operating in the Naval and Defense sectors lead the way for technological development as to manufacturing methods of complex parts, still the basis of the CURTI working method.

The mastery ability to optimize processes combined with specific skills for these processes and the related non-destructive tests have allowed us to move from a traditional third-party account to co-engineering activities.

CURTI participates and proactively supports the design of machines and complex systems for all its customers, using advanced design software such as CREAO, CATIA, PRO-E, and others.

Today CURTI’s production plants extend over 60,000 square meters, of which about 30,000 are covered.

Our numbers

Products & Services

CURTI operates as “TIER1”, with maximum capacities in the context of the most extreme verticalization of the systems and structures required by customers.

The large and differentiated machine tool park allows for the best management of the areas of activity which can be summarized as follows:

• sheet metal processing;

• welding of special alloys;

• mechanical machining of chip removal;

• surface and heat treatments on steel, aluminum, titanium;

• non-destructive tests

We also carry out complex and complete assemblies of aerospace structures.

Main Markets

- Europe

- North America

- Mexico

- Turkey

- China

Certifications

CURTI uses the integrated quality management system and operates in compliance with the following standards

- UNI EN 9100

- ISO 9001

- ISO 14001

- ISO 50001

- ISO 45001

The company is in possession of:

- EA-SA POA Part. 21

- DIN 2303

- ISO 3834

and has Nadcap accreditation for non-destructive testing and for welding.

Top Clients served by the company

-

LEONARDO COMPANY