DTM S.r.l.

Description

Since the year 1994, DTM is specialized in the design, development, and qualification of aerospace structures, testing equipment, and GSE (mechanical, fluidic, thermal) for satellites, launchers, and experiments on both manned and unmanned missions.

Design tools include 3D CAD drafting and modeling software. Also structural, thermal, and fluidic analysis and fracture control analysis software.

DTM facilities include grey areas for integration of small types of equipment, ISO6 cleanroom, tools and test facilities for manufacturing and verification of composite parts (autoclave), three thermal vacuum chambers with temperature ranges from cryogenic up to 200°C and above, static and fatigue test jigs, shaker and acquisition systems.

DTM head office and laboratory are located in Modena (1100 m2).

A second laboratory/integration area is located in Bastiglia (Modena) and hence provides a 500 m2 total area (including an ISO 8 cleanroom) for integration and testing of large types of equipment, structures, and testing facilities (20 tons crane).

Our numbers

Products & Services

- Mechanical Design and analysis

DTM can develop full turnkey projects taking care of all design (drafting) and structural and thermal verification activities,

Thanks to his 3D CAD, FEM, and CFD software tools DTM can also work on specific design activities.

- Engineering and testing service

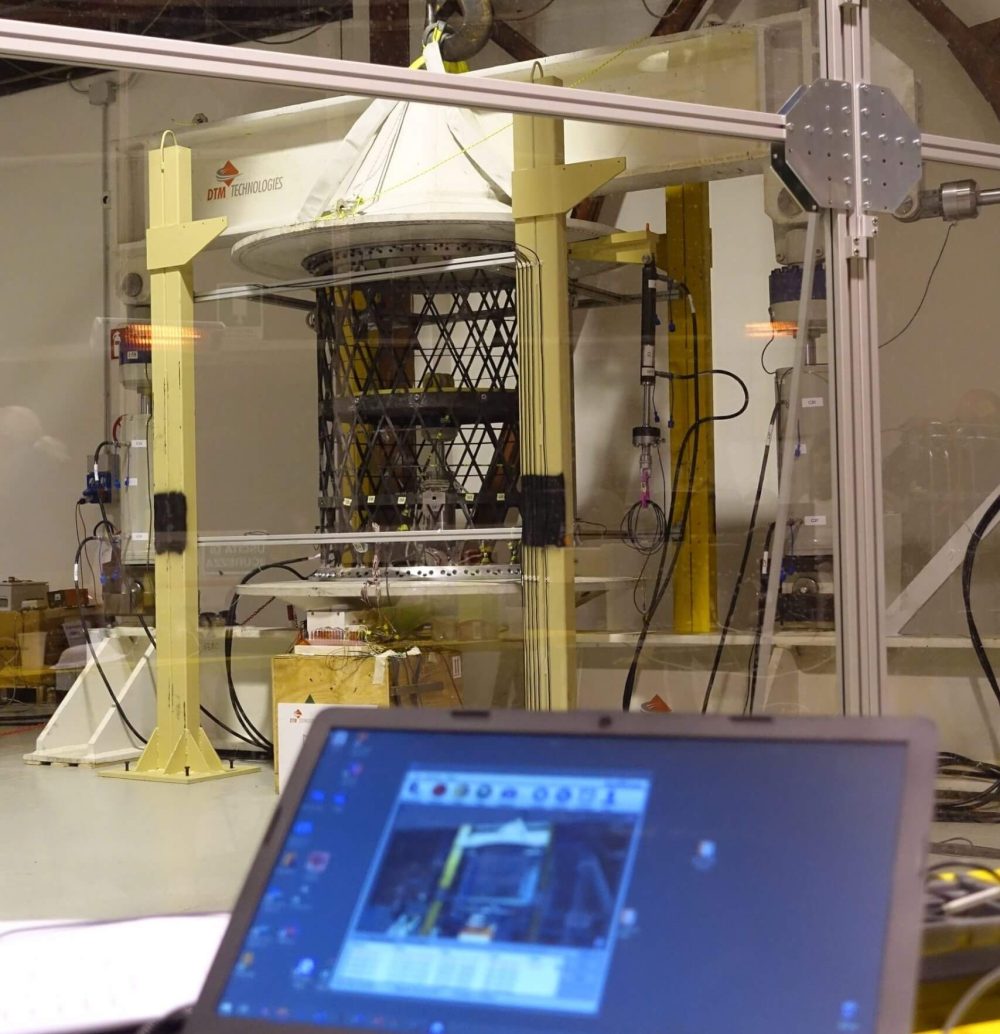

DTM offers engineering and testing services, including the design of the full experimental (mechanical, electronic, fluidic) and acquisition types of equipment like test jigs to qualify space structures (Vega Interstage, Tank support structures). DTM is a qualified laboratory of Emilia Romagna High Technology Network.

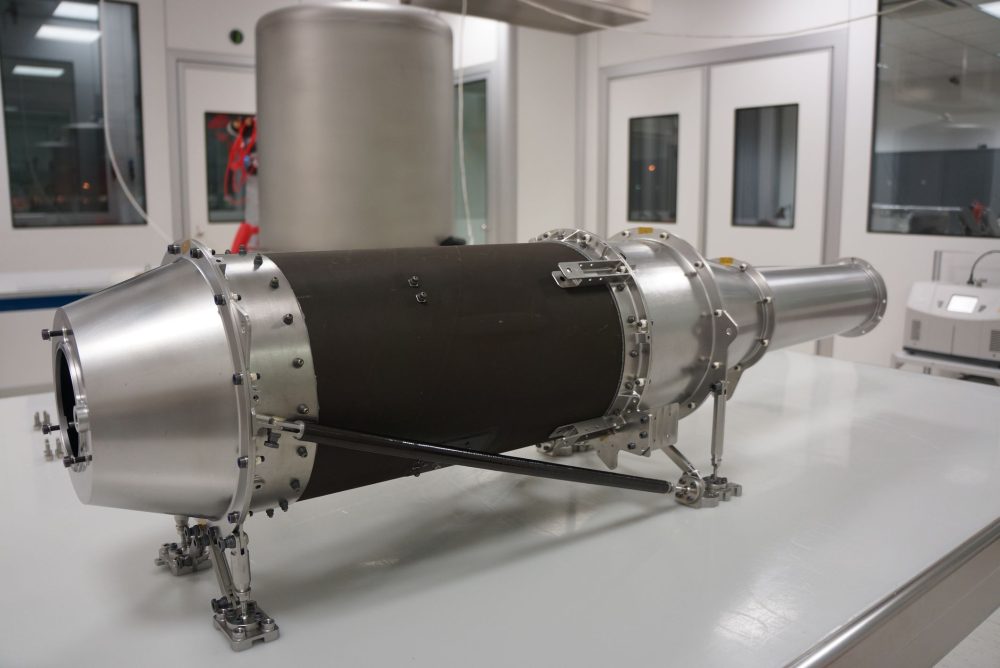

- Satellite and launcher structures

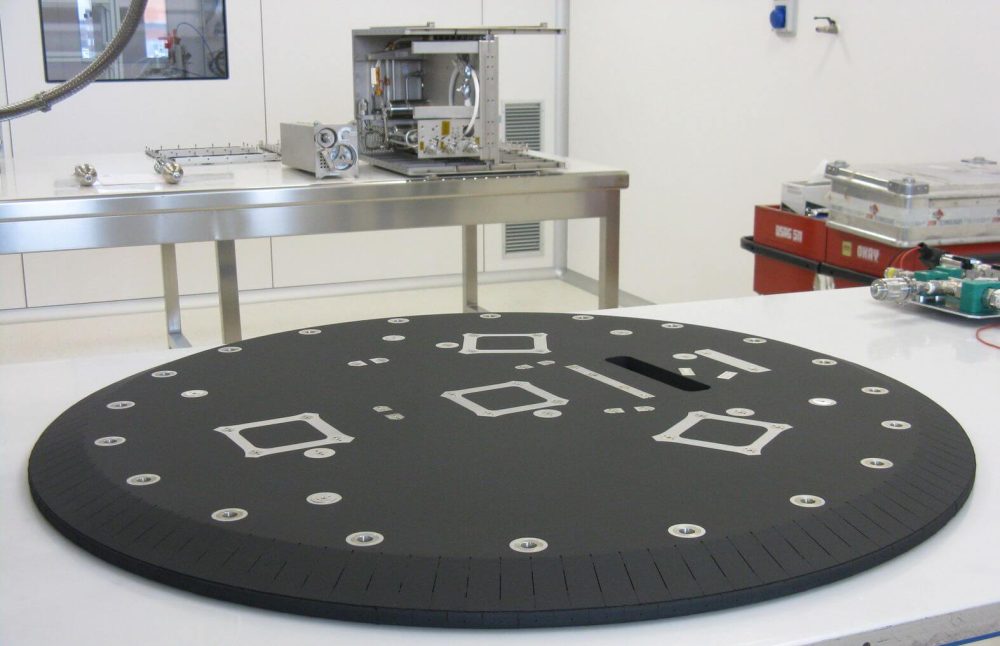

DTM is qualified for realizing composite or metallic sandwich panels like the Exomars sandwich panels developed for Thales Alenia Space Rome and Prisma primary and secondary structures for OHB and instrument structures for Leonardo (ASI Program). For Thales Alenia, Space DTM realized the composite thrust structure of the IXV space vehicle.

- Space products

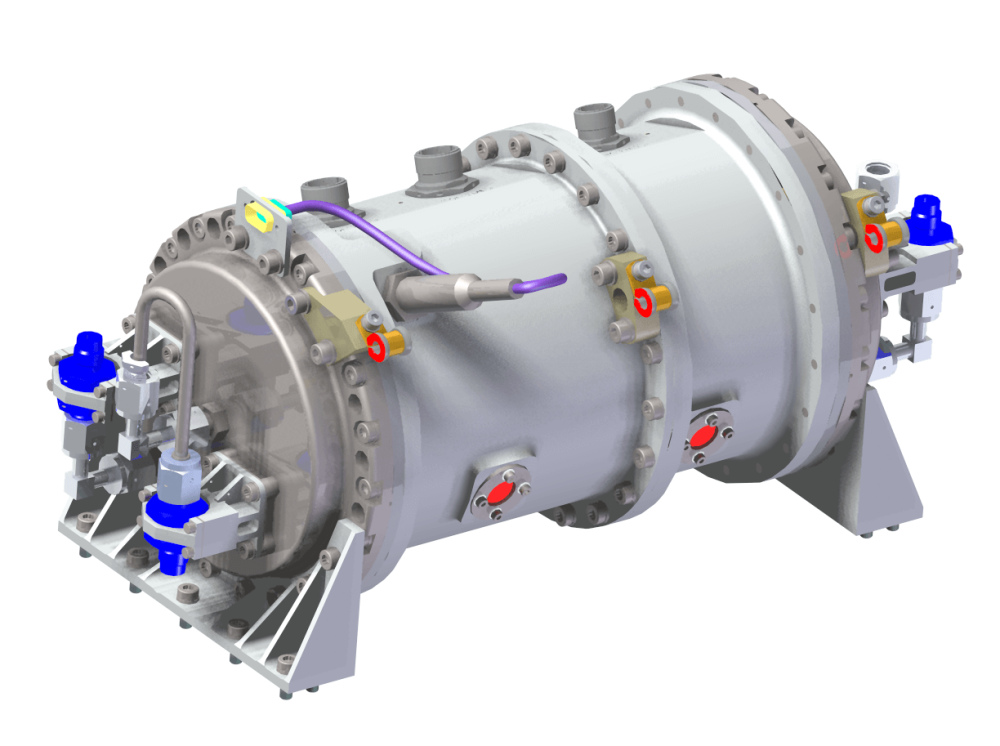

DTM designs and develops heat exchangers for ISS and space vehicles, as the well-known heat exchangers for the Orion Multi-Purpose Crew Vehicle (prime Thales Alenia Space).

DTM also develops custom flight components for challenging applications like the filling valve for Exomars Ultra Clean Zone Analytical Laboratory Drawer.

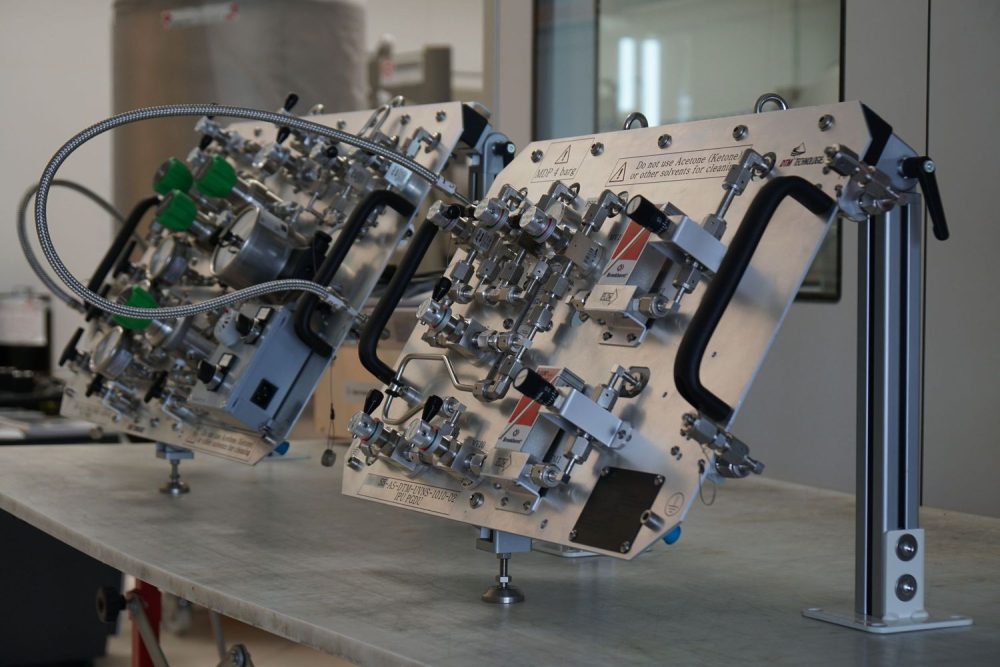

- Mechanical and Fluidic Ground Support Equipments

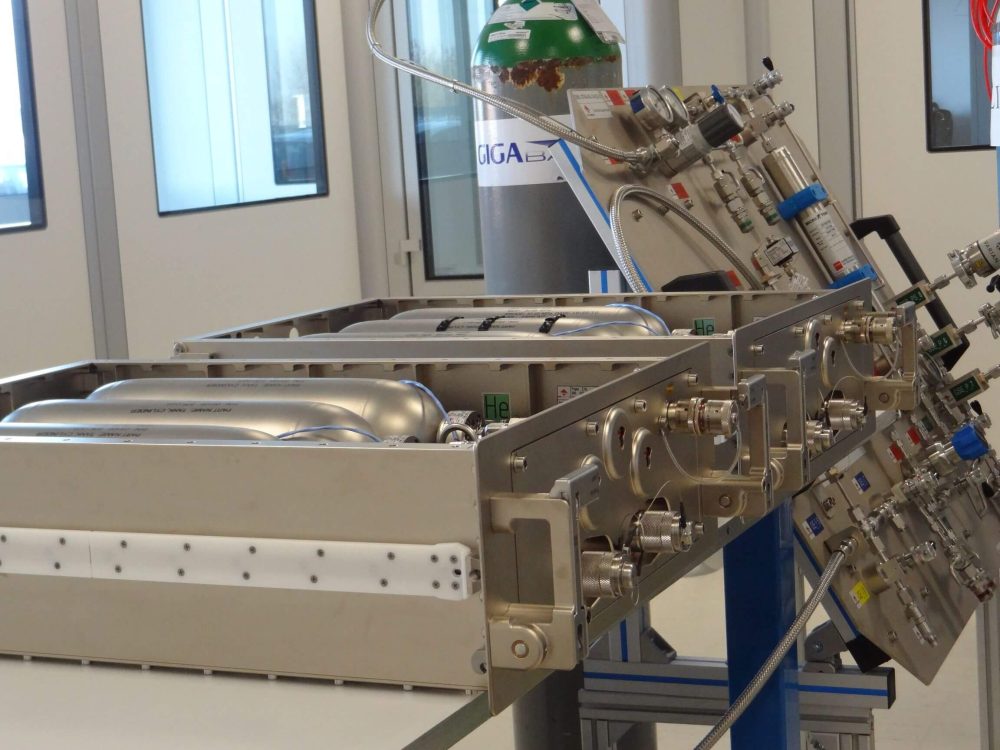

DTM designs and develops mechanical and fluidic ground support types of equipment (M/F-GSE) for instruments and satellites handling, integration, purging, and transportation. DTM built several mechanical and fluidic GSEs for the principal European prime contractors.

Main Markets

- Europe

Certifications

DTM quality management system is certified according to:

- UNI EN ISO 9001:2015

- UNI EN 9100:2018

Top Clients served by the company

-

AIRBUS DEFENCE AND SPACE

-

THALES ALENIA SPACE

-

OHB

-

EUROPEAN SPACE AGENCY

-

CIRA - Italian Aerospace Research Centre

-

ASI - Agenzia Spaziale Italiana